Stephen Boedo Offset journal bearings are an attractive design option for cross-head and. Maximum stroke can be a maximum of about one-third of the slide length but the.

Engineering Basics Guide To Bearings Eriks Shop Nl

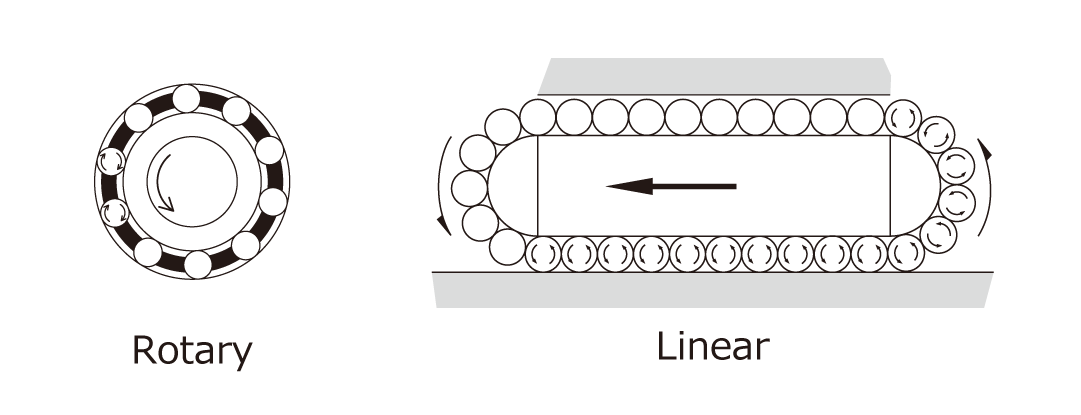

Since linear bearings have become important primarily as a result of robotic automation one must often refer to manufacturers literature for loadlife formulas.

. 18 Years Factory Mechanical Design Guidelines For Bearings - QW Series Wide Rail Linear Guideway Xingyun Detail. World there are several standards for through hardened bearing. Assembly of most ball bearings is as follows.

Consistently extreme temperatures. Ball bearings are used primarily to support rotating shafts in mechanical equipment. When bolting components together in order to make the bolted joint act almost as it were welded together the bolts strain stress cones should overlap.

3 to prevent the locking device interfering with the seal. 10 Figure 3 Ball Bearing Material 11. A bearings smooth performance is assured by a combination of four basic working parts fig.

Self-aligning ball bearings with a tapered bore can be mounted with. Sliding bearings have existed since the first skid-supported wheel barrow was used by primitive man. A sliding bearing typically uses a lubricant to reduce friction between the sliding surfaces.

A shaft and bushing bearing is known as a journal bearing. Thesis Advisor Department of Mechanical Engineering Dr. Maintenance Free Operation - Self-lubricating bearings solve the problem of oiling operation and oiling devices also saving bearing maintenance costs.

Simplified Mechanical Design And Manufacture - With above advantages thin wall thickness higher load and excellent wear resistance mechanical designs can be simplified and made more economical. FEATURE The HIWIN QW series linear guideway with SynchMotionTM Technology possesses all the advantages of the WE series which features high moment rigidity and is suitable for single rail or space saving applications. A short summary of this paper.

For air bearing guide material surface finish its recommended to opt for a 16rms finish or better than this one. Mechanical Design Fundamentals K. Mechanical Design Guidelines For Bearings With our leading technology also as our spirit of innovationmutual cooperation benefits and development we are going to build a prosperous future jointly with your esteemed company for Mechanical Design Guidelines For Bearings Guide Bearing And Thrust Bearing Mini Linear Guide child face mask disposable Curved Linear.

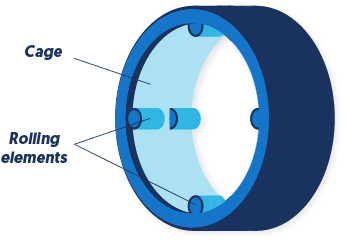

¾ The separator is installed. It also tends to be heavier than a modular design since all of the carriage or base needs to a single monolithic piece of hardened steel. Outer race also called outer ring or cup Inner race also called inner ring or cone Rolling elements either balls or rollers Separator also called cage or retainer The outer race or cup is the bearings exterior ring.

A linear ball slide is a compact form of linear bearing with a small form factor and a similarly short stroke. Friction The construction of Linear Guide are block rail and motion system which has rolling elements such as balls and rollers placed between two raceways. Use appropriate SKF adapter sleeve assemblies for sealed bearings eg.

The chapter also presents an overview of technologies which serves as building blocks for machinery and mechanical design. Alternatively a spacer ring can be inserted. Craig 25 In machine tool structure if one is to minimize bending the length of the structure should be no more than 3-5 times the depth of the beam.

E design sleeve fig. Select 2 - Journal Bearings. Bearing face is also susceptible to damage during a touchdown as its in motion.

If youre working on small gaps then the surface roughness can become a problem as it adds to the gap so the design can be influenced. Modular Linear Crossed Roller Bearings. This chapter introduces the design process from an inventors perspective the double diamond model and more formal approaches such as systematic total and blended design.

With the invention of the wheel efficient and robust bearings became a necessity since so much force is applied to the small area of the bearing surface. ¾ The balls are loaded inside the crescent shape that is formed. Bearings can be classified as providing sliding or rolling contact.

The raceway inserts are made from hardened steel rods which are cut in half and. Linear Ball Bearings as their name implies are linear bearings where the rolling contact is provided by hardened and ground balls. An adapter sleeve on plain a or stepped shafts b SKF adapter sleeves are supplied complete with a locking device.

¾ On a flat surface the inner ring is placed off-center inside the outer ring. Predicted values meet actual design requirements. Design Guidelines for Offset Journal Bearings in Two-Stroke Engines David P.

Total interference fit 00003 in. ¾ The inner ring is centered and the balls evenly spaced. You can use rough surfaces as well.

The fluid lubricant forms a film between the sliding. Tight 80 of interference fit 00003 080 000024 in. 37 Full PDFs related to this paper.

The modular CRB is lighter than the low-profile design since most of the carriage and base can be made from aluminum. The rolling motion that rolling elements give rise to reduce the frictional resistance to 120 th to 140 th of that in a. Mechanical Design Guidelines For Bearings Mariners Repository Bearings Design Guidelines - magnitude and direction of the thrust load if any.

Although plastic bearings can function well at nearly 500F for short periods of time they cannot handle extreme temperatures for long-term operations. Full PDF Package Download Full PDF Package. Radial play of bearing 00002 in.

Hany Ghoneim Professor Committee Member Department of Mechanical Engineering. LoadLife Calculation Linear bearings undergo reciprocating rather than rotary motion so that accelerations are much higher than typically experienced by rotary bearings. Bearings are needed whenever one part of a machine slides against another.

Linear Bearings Understanding The 2 1 Ratio And How To Overcome The Stick Slip Phenomenon Machine Design

Gear Terminology Basics Of Gear Smlease Design Mechanical Design Basic Design

Mechanical Design Guidelines For Bearings

Linear Guides Linear Motion Guides Design Selection And Technical Faq Global English

What Is Poisson S Ratio Design Basics Mechanical Design Design

2021 The Most Detailed Abec Rating Guide The Abec Scale Is An Industry Accepted Standard For The Tolerances Of A Ball Bearing I Evaluation System Guide Scale

Linear Bearings Understanding The 2 1 Ratio And How To Overcome The Stick Slip Phenomenon Machine Design

0 comments

Post a Comment